This term refers to the fourth industrial revolution and envisions a production process based on the connection between physical and digital systems, complex analyses through Big Data and real-time adaptations. In other words: use of web-connected machines, analysis of information from the web and the possibility of more flexible management of the production cycle. Enabling technologies range from 3D printers to robots programmed for certain functions, via cloud-based data management and data analysis to detect production weaknesses and strengths. It is the IoTIoT The ‘Internet of things’ is the idea of networking any device with a power button. Paradoxically, this can be anything, from mobile phones to coffee machines, washing machines, refrigerators, vacuum cleaners, headphones, lamps, and wearable devices. This also applies to internal machine components, such as sensors in a car. This immense network of connected objects could improve many aspects of our lives: imagine a refrigerator which, by reading the barcodes of the products it stores, could tell us what is about to expire and what has run out, allowing it to suggest a shopping list. A coffee machine that switches on at the right time knowing the alarm time set on your smartphone, a car that suggests the best route to take based on traffic information sent by other cars. applied to industrial production.

28.03.24

Tecnology and Innovation

Blockchain and FTTH fiber-optic network, all the advantages in healthcare

Blockchain technology enables reliable and transparent data management. This offers many advantages in healthcare In recent years, there has been a revival of interest in blockchain: this technology can provide greater security and efficiency in the management of information, making it the preferred solution for data processing, especially in the health sector. We take a […]

29.02.24

Tecnology and Innovation

What is Challenge Based Learning (CBL), the new way of learning in school 4.0

CBL is a learning method based on finding a solution to a concrete challenge. Here we reveal how it works and how FTTHFTTH “Fiber to the Home” is the technology that connects POPs, located in exchanges, to end users’ property units with fiber optics. fiber optics is its trusted partner The digital evolution in education […]

29.02.24

Open Fiber World

TeleSmeg project: new digital solutions for a zero-emission future

New digital solutions to optimise the energy management process: this is the goal of TeleSmeg, a project conducted as part of the RESTART programme. The energy transition cannot be separated from the digital transition: this is the idea behind TeleSmeg, the ambitious project conducted as part of the RESTART research and development programme, for which […]

09.02.24

Open Fiber World

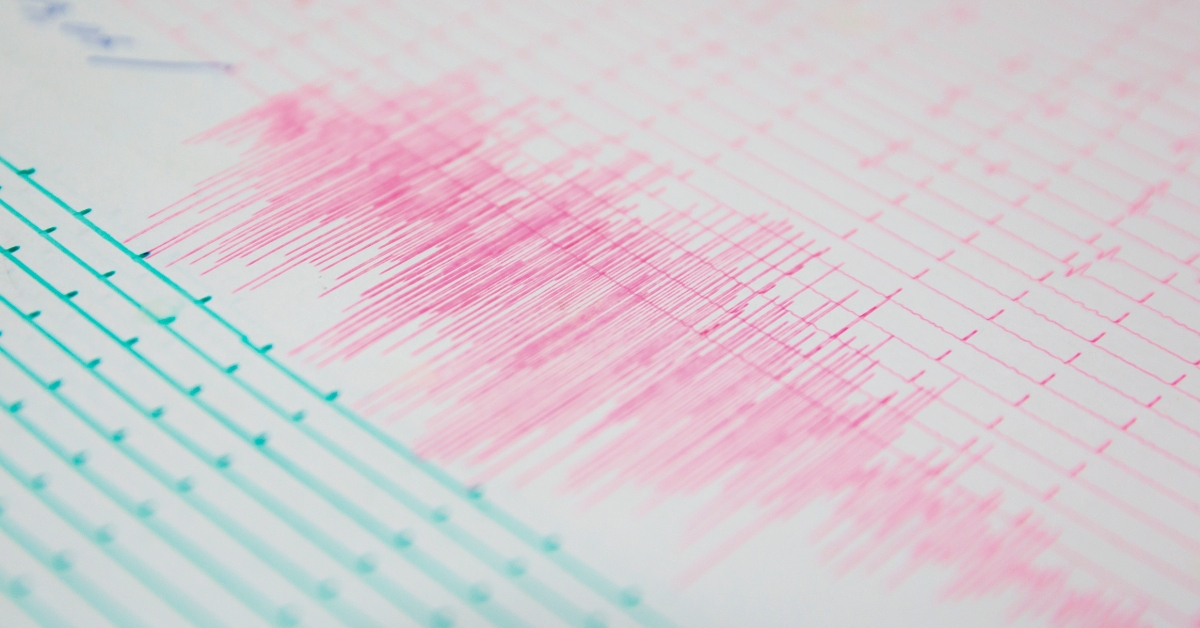

FAAS project: even more efficient FTTH fiber optic for seismic monitoring

Discovering the FAAS project, a further step in the use of FTTHFTTH “Fiber to the Home” is the technology that connects POPs, located in exchanges, to end users’ property units with fiber optics. fiber optic for seismic sensing. A collaboration with the Politecnico di Torino, the National Institute of Geophysics and Volcanology (INGV), and the […]

01.02.24

Connectivity as a primary need: data from the EY survey

According to a recent EY survey, in spite of rising prices, connectivity remains a primary need for citizens. What role does Open Fiber play? Connectivity is a primary need for citizens, according to the recent EY survey ‘Decoding the digital home study’. The survey, conducted on 2,500 households in Italy and over 20,000 globally, analysed consumer […]